Pulse Width Modulation (PWM) is a technique used to control analog devices using digital signals.

It is widely used for motor speed control, LED dimming, and communication applications.

Most PIC microcontrollers include CCP (Capture/Compare/PWM) modules that allow precise PWM signal generation with minimal CPU intervention.

Understanding PWM in PIC Microcontrollers

A PWM signal consists of:

- Frequency: How often the signal repeats per second.

- Duty Cycle: The percentage of time the signal is HIGH within one period.

Formula:

Duty Cycle(%)=(Total Period/ON time)×100

Example:

- If a 1 kHz PWM signal has a duty cycle of 50%, it means the signal is HIGH for 0.5ms and LOW for 0.5ms.

CCP Module Overview

The CCP (Capture/Compare/PWM) module in PIC microcontrollers supports PWM mode, where it generates a periodic pulse with adjustable duty cycle.

CCP Registers for PWM Mode

| Register | Purpose |

|---|---|

| CCP1CON | Configures CCP module for PWM mode |

| CCPR1L | Holds the 8 Most Significant Bits (MSBs) of the duty cycle |

| CCP1CON<5:4> | Holds the 2 Least Significant Bits (LSBs) of the duty cycle |

| TMR2 | Timer 2 provides the time base for PWM |

| PR2 | Defines the PWM period |

| T2CON | Configures Timer 2 (prescaler and enable bit) |

PWM Frequency Calculation

The PWM frequency is determined by the PR2 register and the Timer 2 prescaler.

PWM Period=(PR2+1)×4×Tosc×Prescaler

PWM Frequency = 1/PWM Period

Where:

- Tosc=1FoscT_{osc} = \frac{1}{F_{osc}} (Clock cycle time)

- FoscF_{osc} is the oscillator frequency

- PR2 is an 8-bit register (0 to 255)

- Prescaler can be 1, 4, or 16

Example Calculation

If:

- Fosc=8MHzF_{osc} = 8MHz

- PR2 = 124

- Timer2 Prescaler = 16

PWM Period = (124+1)×4 × 1/8MHz ×16

PWM Frequency = 1/(125 × 4 × 1/8MHz × 16)

PWM Frequency = 1kHz

Setting PWM Duty Cycle

The PWM duty cycle is controlled using CCPR1L and CCP1CON<5:4> bits.

Duty Cycle (10-bit)=(CCPR1L:CCP1CON<5:4>)×Tosc×4\text{Duty Cycle (10-bit)} = \left( CCPR1L:CCP1CON<5:4> \right) \times T_{osc} \times 4

- CCPR1L holds the upper 8 bits.

- CCP1CON<5:4> holds the lower 2 bits.

Example

For 50% duty cycle on a 1 kHz PWM:

Duty Cycle (10-bit)=125×42=250\text{Duty Cycle (10-bit)} = \frac{125 \times 4}{2} = 250

- CCPR1L = 0x3E (62 in decimal)

- CCP1CON<5:4> = 0b10

Implementing PWM on PIC Microcontroller

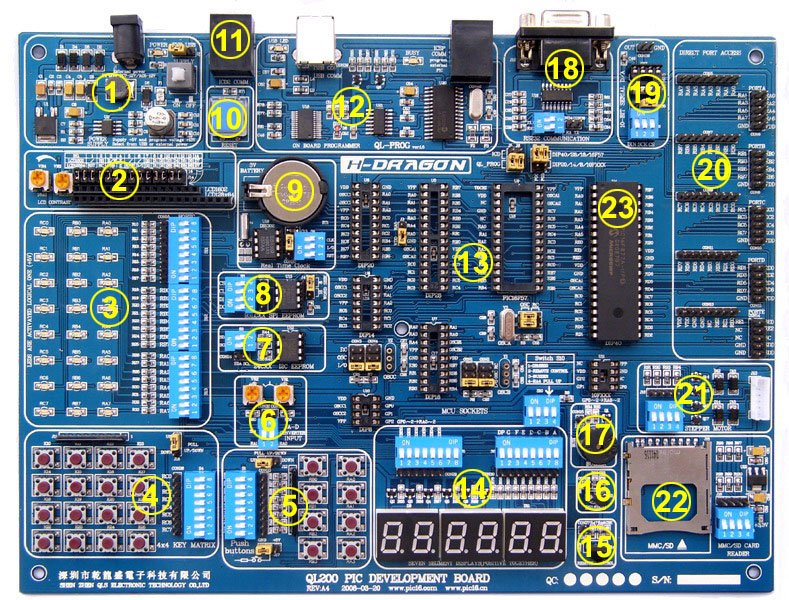

We will configure PWM using CCP1 module on a PIC16F877A to control LED brightness.

Hardware Requirements

- We used a PIC16F877A microcontroller

- 8 MHz external crystal

- LED with resistor (330Ω)

- Power supply (5V)

Circuit

- PWM output is on RC2 (CCP1 pin).

- The LED is connected to RC2 with a 330Ω resistor.

PIC PWM Code Example

We used MPLAB X with the XC8 compiler for this example

#include <xc.h>

// Define Configuration Bits (For PIC16F877A)

#pragma config FOSC = XT // Oscillator Selection

#pragma config WDTE = OFF // Watchdog Timer Disabled

#pragma config PWRTE = OFF // Power-up Timer Disabled

#pragma config BOREN = ON // Brown-out Reset Enabled

#pragma config LVP = OFF // Low Voltage Programming Disabled

#define _XTAL_FREQ 8000000 // Define clock frequency (8MHz)

void PWM_Init(unsigned int frequency);

void PWM_DutyCycle(unsigned int duty);

void main() {

TRISC2 = 0; // Set CCP1 (RC2) as output

PWM_Init(1000); // Initialize PWM with 1 kHz frequency

while(1) {

PWM_DutyCycle(512); // Set 50% duty cycle (512 out of 1023)

__delay_ms(1000);

PWM_DutyCycle(256); // Set 25% duty cycle (256 out of 1023)

__delay_ms(1000);

PWM_DutyCycle(768); // Set 75% duty cycle (768 out of 1023)

__delay_ms(1000);

}

}

// Function to Initialize PWM

void PWM_Init(unsigned int frequency) {

unsigned int PR2_value;

PR2_value = (_XTAL_FREQ / (frequency * 4 * 16)) - 1;

PR2 = PR2_value; // Set PR2 for the required PWM frequency

CCP1CON = 0x0C; // Configure CCP1 as PWM mode

T2CON = 0x04; // Enable Timer2 with Prescaler = 1

// Start Timer2

TMR2 = 0;

TMR2ON = 1;

}

// Function to Set PWM Duty Cycle (0 to 1023)

void PWM_DutyCycle(unsigned int duty) {

CCPR1L = duty >> 2; // Upper 8 bits

CCP1CONbits.DC1B = duty & 0x03; // Lower 2 bits

}

Explanation

- Initialize PWM (PWM_Init())

- Configures CCP1 module in PWM mode.

- Calculates PR2 value for the required PWM frequency.

- Enables Timer2 with an appropriate prescaler.

- Set Duty Cycle (PWM_DutyCycle())

- Converts 10-bit duty cycle value into 8-bit (CCPR1L) and 2-bit (CCP1CON<5:4>) values.

- Main Loop

- Changes LED brightness by setting different duty cycles (25%, 50%, 75%).

Summary

| Step | Description |

|---|---|

| 1. Configure CCP1 | Set CCP1CON = 0x0C for PWM mode |

| 2. Set Timer2 | Configure T2CON for PWM timing |

| 3. Calculate PR2 | Use formula to determine PR2 for desired frequency |

| 4. Set Duty Cycle | Adjust CCPR1L and CCP1CON<5:4> |

| 5. Enable PWM | Start TMR2 |

Applications of PWM

- Motor Speed Control

- LED Brightness Control

- Analog Signal Generation

- Audio Signal Processing

This tutorial covers everything needed to generate PWM signals using PIC CCP module